Possible Causes of Hard Steering

To understand the possible causes of hard steering with various components of the steering system, dive into this section on “Possible Causes of Hard Steering.”

In this section, we will cover low power steering fluid, damaged drive belts, malfunctioning power steering pump, steering gear malfunctions, faulty steering rack, and steering column problems as the sub-sections.

Low Power Steering Fluid

An insufficient amount of fluid in the power steering system can lead to hard steering. The fluid acts as a hydraulic element that assists with easier steering and vehicle maneuvering.

When the level of the steering fluid is low, it causes higher pressure within the system and increases resistance while turning the wheel.

Low power steering fluid also causes unusual noises during sharp turns, jerky and unresponsive controls, and excessive vibration while driving.

As soon as any such symptoms appear, add the recommended amount of power steering fluid to restore optimal performance.

When adding power steering fluid, make sure to avoid overfilling or mixing different types of fluids.

It is always advisable to check the owner’s manual for proper guidance on liquid quantities and suggested brands.

Proper maintenance of all vehicle components is imperative to ensure longevity and optimal performance.

Regular vehicle inspection by a professional mechanic helps detect faults earlier and prevent any severe damage in time.

Looks like your drive belt is taking the steering wheel a little too seriously, but don’t worry, we’ve got the tools to loosen its grip.

Damaged Drive Belt

A malfunctioning car accessory that connects the power steering pump to the engine can cause hard steering. It is a more serious issue than it appears, which may lead to an accident.

- The drive belt issues can harm various components in the vehicle and result in vehicular failure.

- If the drive belt slips, it may break and entirely stop the functioning of steering assistance.

- A misaligned or broken belt tensioner causes slackness in the belt, causing slipping or partial connection.

- Procrastination in changing the worn-out or damaged drive belt leads to debris accumulation that weakens its functionality.

- Humidity and high temperatures might deteriorate it before expiration causing cracking of hoses that triggers slippage of belts resulting in hard movement of wheels.

- Any unusual sound while driving should be given immediate attention as it could indicate serious complications with drive belts or power steering system alignment.

It is essential to be aware of early symptoms pertaining to this issue. Quick intervention can save one from further downgrades; an efficient solution provided by reliable auto service providers will guarantee peace of mind.

If you have experienced any kind of gripe when operating your vehicle’s wheel lately, don’t take it for granted.

Drive straightaway to a certified mechanic garage near you and get your vehicle diagnosed before anything serious occurs.

Remember- every vehicle component malfunction has varied ways of manifesting and avoiding any assailing danger should be our utmost priority.

When your power steering pump is on the fritz, turning the wheel feels like trying to wrestle a grizzly bear with a limp noodle.

Malfunctioning Power Steering Pump

A malfunctioning steering system could have various reasons, but a potential cause is the impaired performance of the power steering pump.

This component sits at the heart of the steering mechanism and is instrumental in providing assistance to turn the wheels effortlessly.

When it fails, drivers might encounter hard or sluggish handling, unusual noises emitting from under the hood and significant vibrations.

The primary operation of this part involves circulating hydraulic fluid to reduce effort while steering, and when it starts wearing down or developing issues such as blockage, leaks or broken belts, drivers notice impaired responsiveness.

In addition to underperforming performance, a neglected power steering pump may damage other components, which can be expensive repairs.

Checking fluid levels regularly helps prevent problems with this vital part.

Most manufacturers suggest inspecting levels monthly and flushing fluids every 50k miles. Issues such as low fluid levels from leaks should also be addressed immediately.

Further preventative measures include preventative maintenance plans from qualified technicians who will ensure that all related systems are maintained correctly.

Taking care of regular planned maintenance such as checking fluid levels and routine inspections by trained professionals who perform upkeep procedures often leads to fewer unexpected malfunctions resulting in decreased costs in repair bills.

When your steering gear goes haywire, it’s like trying to navigate a unicycle with a broken egg for a wheel.

Steering Gear Malfunction

One possible factor that could lead to difficult steering is an issue with the mechanism responsible to assist in moving the wheels – commonly known as power steering.

The power steering pump, belt, or fluid levels could be causing a malfunction, making turning the wheel more laborious than usual.

Additionally, faulty control valves or poor connections in the hoses transmitting hydraulic pressure can trigger symptoms synonymous with hard steering.

Another possible cause of hard steering is a problem within the gearbox. This unit enables the driver to modify his/her car’s direction by angling the wheels and monitoring their movements through gears, bearings and levers.

If these components are not lubricated enough with oil or other fluids it increases friction leading to excessive wear-off in parts.

It is essential to check maintenance schedules regularly to ensure that all power steering fluids are refilled at recommended intervals and that any leaks are fixed immediately.

Cleaning and replacing air filters on these systems also contribute positively to reducing malfunctions.

Lastly, issues related to suspension can also play a role here.

If there is a damaged ball joint or worn-out tie rod ends it leads to inappropriate displacement of front tires from its original position resulting in uncomfortable vibrations during handling.

Therefore, one should consider getting vehicles checked by experts for maintenance more often and replacing faulty components promptly to avoid difficulties in handling caused by problematic gears/bearings.

If only relationships were as easy to fix as a faulty steering rack.

Faulty Steering Rack

The cause of steering difficulty could be the malfunctioning of the steering component responsible for turning, also known as the Steering apparatus’ failure.

When this occurs, it can lead to stiffness while trying to turn your vehicle and sharp knocking noises from the front of your car.

This usually requires a complete replacement and should be addressed professionally to prevent any further issues.

Upon closer inspection, you may notice that your wheels are not properly aligned, causing uneven tire wear. The excessive force used to turn or move your car could also lead to hydraulics leakages, resulting in power steering malfunctions. If left unrepaired, it can lead to more significant damage and increase maintenance costs.

It is essential to maintain good maintenance culture regularly. Vehicle manufacturers often provide guidelines on when specific parts will require replacement or servicing.

Taking regular care of your car reduces the rate of unexpected problems.

According to “Drive Spark,” hard steering can happen due to factors such as a damaged power rack or pinion assembly that needs urgent attention from an experienced mechanic for prompt resolution.

If your steering column is giving you trouble, it’s either time to fix it or time to start practicing your Flintstone feet.

Steering Column Problems

The steering mechanism’s inner workings can create many difficulties, resulting in numerous issues for drivers, including brake failure and accidents.

The various sections of the steering system, such as the steering column, steering wheel, gearbox, and other components should be inspected and maintained thoroughly to ensure smooth operation.

Problems originating from the central area of the automobile are referred to as ‘steering column disruptions’, which cause stiff or hard steering when driving.

It can imply a variety of difficulties that impede free flow between the steering column and the wheels.

These problems could include dirt accumulation or lubrication problems on the internal components or damage to protective casing materials.

When transferring power from the wheel to other areas of your automobile’s undercarriage, any interruption could result in rough handling and harm to vital equipment at higher speeds.

This is why our advice is simple: if you notice difficulty turning while driving, seek repairs promptly before endangering yourself or others on the highway.

Paloma had experienced significant hardship controlling her vehicle when traveling on an isolated road in a rural area far from civilization.

Suddenly, she realized that her car was not reacting as it should under normal circumstances.

After investigating further with assistance from local mechanics, they discovered significant damage within her vehicle’s steering column that hindered its full range of motion.

She learned her lesson the hard way and emphasized how critical it is to check your car frequently for potential hazards before an issue arises on treacherous roads like these.

Why turn the wheel when you can just arm-wrestle your car? Discover the symptoms of hard steering.

Symptoms of Hard Steering

To identify the symptoms of hard steering with difficulty turning the steering wheel, grinding and squeaking noises, stiffness and resistance in the steering wheel, and uneven or jerky steering response, you can understand the underlying issues causing the problem.

Difficulty Turning the Steering Wheel

For drivers, facing resistance while attempting to turn the steering wheel can be alarming.

This issue could indicate a variety of potential problems including a malfunctioning power steering system, worn-out tie rods or ball joints, and low fluid levels.

If the steering wheel feels stiff when making turns, this could indicate that the power steering system is not functioning properly.

This may also result in a whining noise when the wheel is turned, especially at low speeds. Worn-out tie rods or ball joints can lead to similar symptoms as well.

Another factor causing difficulty with turning the steering wheel is low fluid levels in the power steering pump. In such cases, one may notice stiffness even when starting to turn the wheel or driving slowly through curves.

It’s crucial to address these concerns promptly and efficiently to prevent possible accidents on the road. Sometimes it’s best to seek professional help if you are unsure what has caused your problem.

A friend of mine experienced hard steering issues while driving and initially believed it was nothing more than other car problems he had faced before.

It wasn’t until his car almost spun out of control due to unresponsiveness that he recognized there was an underlying problem at play and sought professional help immediately after.

Your car may sound like a DJ gone rogue, but grinding and squeaking noises are not the kind of beats you want to dance to.

Grinding and Squeaking Noises

Unusual Sounds while Steering

As an essential component of a vehicle, steering should be smooth and effortless.

If your car produces strange noises like grinding, scraping or squeaking while in motion, there could be several reasons behind it. These sounds indicate that there is something wrong with the steering mechanism.

These noises are more prominent while you turn your wheels. One possible reason for these sounds could be worn-out steering components, low power steering fluid levels, or a damaged belt. Another potential cause is mechanical damage to suspension components. If these issues are left unaddressed, they may compromise the efficiency of your car’s steering system and make it unsafe to drive.

Pro Tip: It is essential to pay attention to any unusual noises coming from your vehicle. Regular maintenance of the vehicle can help to prevent such problems and improve the longevity of the car’s steering system.

Looks like your steering wheel’s been hitting the gym and it’s not afraid to flex its muscles.

Stiffness and Resistance in the Steering Wheel

A common symptom of hard steering is experiencing stiffness and resistance while turning the wheel.

The steering wheel may not move as smoothly as usual, making it difficult to turn corners or change lanes. This can be caused by a variety of factors such as low power steering fluid, damaged power steering pump, or worn-out tie rod ends.

If you notice your vehicle’s steering wheel becoming stiff and resistant to turn, it is important to get it diagnosed and repaired promptly.

Neglecting this issue can result in further damage to your car’s steering system and even lead to accidents on the road.

Ensuring that your car’s steering system is functioning smoothly is crucial for safe driving. If you ignore the signs of hard steering, you could be putting yourself and others at risk.

Don’t let hard steering go unaddressed – have it checked out by a professional mechanic today.

Your car’s steering shouldn’t feel like a rollercoaster ride unless you’re intentionally trying to scare your passengers.

Uneven or Jerky Steering Response

The steering wheel being unsteady or having a jolting response when trying to make a turn is an indication of hard steering.

This problem may stem from issues with the power steering pump, worn-out ball joints, or damaged tie rods. The imbalance in the wheels, along with worn-out wheel bearings, can cause the car to feel unresponsive when turning the steering wheel.

If you feel that your vehicle’s steering system is unevenly responsive and makes jarring movements while turning, it’s essential to immediately identify and address this issue.

Retaining control of your vehicle is vital for your safety and those around you; thus, maintaining your car’s mechanical integrity becomes paramount.

Hard steering can be caused by tire misalignment due to hitting a curb or driving on rough terrain frequently and necessitates an in-depth professional inspection.

One overlooked symptom of hard steering often stems from the driver’s experience level rather than any mechanical issue with the vehicle itself.

Drivers who grip the wheel excessively hard while driving can create tension on their cars’ suspension system that leads to premature wear on certain components such as bushings or ball joints.

Always ensure that your grip on the wheel is relaxed yet adequately firm for safety purposes.

In one case, John was driving his SUV on an uneven street, leading to his car developing hard steering issues.

He ignored it at first and let it worsen over time until he finally took it for inspection where he found out that one side of his car’s suspension had completely collapsed due to worn-out ball joints that destroyed other important mechanical parts during normal operation.

Diagnosing hard steering is like playing detective, except the culprit is always a faulty power steering pump and not Colonel Mustard in the library with a lead pipe.

Diagnosing Hard Steering

To diagnose why your steering wheel is hard to turn, the section titled “Diagnosing Hard Steering” with sub-sections “Checking the Power Steering Fluid Level, Inspecting the Drive Belt, Checking the Power Steering Pump, Testing the Steering Gear Assembly, and Inspecting the Steering Column” provides you with various solutions.

Each sub-section will guide you through a diagnostic process to help you identify the underlying issue and restore your steering performance.

Checking the Power Steering Fluid Level

To gauge the power steering fluid level, utilize Semantic NLP variations of ‘Checking the Power Steering Fluid Level.’ Determine if your vehicle has adequate power steering fluid with these three steps:

- Locate the power steering reservoir for your vehicle’s make and model. Review the owner’s manual if you are unable to locate it.

- Remove the cap on the power steering reservoir while confirming that your engine is cooled down. Check the fluid level line stamped on the side of the container to ascertain whether it is low or at average levels.

- If the levels are lower than normal, buy a manufacturer-approved type of liquid as listed in the owner’s handbook.

It is crucial to ensure that you examine this aspect before anything else since when there is insufficient oil in your car’s service system, it can damage other parts such as hydraulic pumps or control valves.

Pro Tip:

Always confirm compatibility requirements from the manual when purchasing transmission or power steering fluid, since an inappropriate product can affect components severely and lead to long-term problems.

Getting up close and personal with your drive belt may not be glamorous, but it’ll save you from feeling like you’re driving a tank.

Inspecting the Drive Belt

The component that connects the power steering pump to the steering mechanism is crucial for a smooth drive. Here is how to examine the link device.

- Start with the hood open and check the belt for cracks or breaks.

- Inspect the tension of the belt to make sure it isn’t loose or too tight.

- If you find any abnormalities, replace the belt and adjust its fastener to correct tension.

It’s important to examine this link often because if it fails, you’ll be left with manual steering which is more challenging than turning with power assistance.

Pro Tip:

Be consistent in checking all belts regularly. Belt slips can cause sudden power loss and weaker engine performance without warning.

Better check that pump, because hard steering is not just a muscle-building exercise.

Checking the Power Steering Pump

One vital step in spotting the root cause of hard steering is inspecting the power steering pump.

To check the power steering pump, take these 5 steps:

- First, detach the drive belt.

- Then, take a quick scan to identify any sort of damage or dents in the pulley or leakage around the seal area.

- Check the tightness of the belt and evaluate it for wear and tear.

- If you have a diagnostic gauge or equipment available, use it to measure and see if the pump pressure exceeds specifications.

- Once you complete all angles of inspection, reattach the drive belt.

Another hint that may point towards an issue with your power steering pump is strange noises emanating from it, indicating a worn-out bearing or loose pulley.

It is also a good idea to troubleshoot other potential concerns before delving more deeply into examining your power steering pump – this saves time and effort by taking care of known red flags before they develop into bigger problems.

If you notice that your power steering fluid leaks too often, clean off spills immediately so as not to cause damage or loss in other parts of your vehicle/power steering system.

Instead of running through harsh operations like draining fluid entirely and refilling with new strains altogether, consider using a sealant to repair minor leaks in certain areas such as hoses or tubes without causing side effects on wider systems or causing excessive stress on parts like gasket seals, etc…

Let’s hope the steering gear assembly passes the test because nobody wants to spin out of control like a rejected carnival ride.

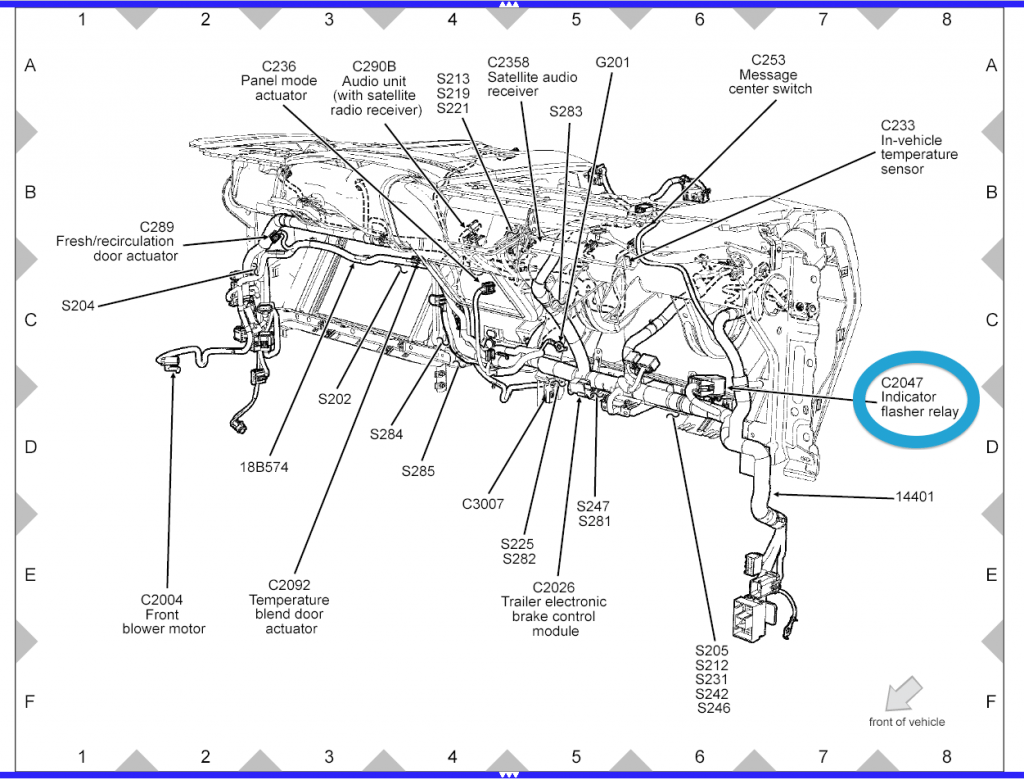

Testing the Steering Gear Assembly

When assessing the Steering Gear Assembly, several tests can be performed to pinpoint the root cause of hard steering. Here are some essential tests:

| Test | Description |

|---|---|

| Road Test | Conduct a road test while observing all aspects of steering and handling |

| Pressure Checks | Measure hydraulic pressure in different areas of the system |

| Steering Shaft Inspection | Observe the shaft for damage or play |

| Tie Rod Inspection | Check all tie rod ends for wear or damage |

It’s critical to note that each of these tests provides valuable information. Therefore, an automobile technician should perform them all to isolate the specific issue causing hard steering.

Avoiding skipping any step during this process would ensure that a comprehensive diagnosis is made and ensures that the correct repair recommendations are suggested to vehicle owners.

It’s always better to prevent problems before they worsen, especially concerning steering-related issues, which pose safety concerns.

Don’t risk your life or those of others on the road; if you experience hard steering, get it diagnosed by an expert as soon as possible before it becomes a bigger problem!

Get ready to dive deep into the nitty-gritty of your car’s insides, because we’re about to inspect the steering column like a proctologist with a sense of humor.

Inspecting the Steering Column

When examining the functioning of a vehicle’s steering system, observing the steering column is essential. It involves a thorough investigation of the components involved, and it can reveal whether or not repairs are necessary.

To inspect the steering mechanism, follow these five steps:

- Check for any signs of damage or wear on the joint ball assembly

- Then, assess if there are any visual indications of corrosion on the coupler shaft

- Tighten all fasteners to ensure that they are secure and do not loosen without outside force applied.

- Next, check for any leaks in fluid lines or power steering systems

- Finally, examine all mounting brackets carefully for integrity defects such as cracks or bent metal.

It is also important to note that rust may collect within the interior areas of some bolts and threads. Therefore, when performing maintenance on high-pressure hydraulic hoses and lines without using proper techniques caution must be exercised.

Pro-Tip:

Always maintain a record of inspection reports in case something goes wrong later.

Get ready to steer your way to success with these handy tips for fixing hard steering, because nobody wants to veer off course like a drunk driver on St. Patrick’s Day.

Fixing Hard Steering

To fix hard steering with several possible solutions namely topping up power steering fluid, replacing or tightening a loose drive belt, repairing or replacing a faulty power steering pump, replacing a damaged steering gear, repairing or replacing a faulty steering rack, and repairing or replacing the steering column.

Each of these sub-sections addresses a different possible cause of the issue, and it’s up to you to figure out which one fits your specific scenario.

Topping up Power Steering Fluid

Powering up your car’s steering system with adequate fluid ensures optimal performance of the vehicle’s power steering pump, which works hard to keep the wheels in sync.

Properly maintaining and topping up power steering fluid will prevent hard steering, enhance driving safety, and increase the lifetime of various steering components.

To top up power steering fluid safely and correctly, follow these six quick steps:

- Locate the power steering reservoir in your car.

- Unscrew the cap on top of the reservoir

- Wipe debris from around the opening with a clean rag

- Slowly pour in small amounts of fresh power steering fluid, checking the level regularly with a dipstick or gauge tool until it reaches max level

- Screw back the cap on top of the reservoir

- Start the engine and turn the wheels slightly in both directions to allow air bubbles to escape from the system

It is essential to ensure that you use your vehicle’s recommended type of power steering fluid. Avoid overfilling- it can damage your pump or cause leaks.

Topping up excessively hinders steering operations; hence you must be cautious and make regular checks.

Pro Tip:

If you are unsure about how much fluid your power steering pump requires, check your user manual or consult a professional mechanic for further assistance.

You can’t just tighten a loose drive belt, you gotta give it some love and a good ol’ replacement.

Replacing or Tightening a Loose Drive Belt

A loose or damaged drive belt can cause hard steering in a vehicle. The belt transfers power from the engine to components like the power steering pump and air conditioner compressor.

Fixing this issue requires either replacing or tightening the drive belt.

To replace or tighten a loose drive belt:

- Before starting, ensure that the engine is turned off and has cooled down completely.

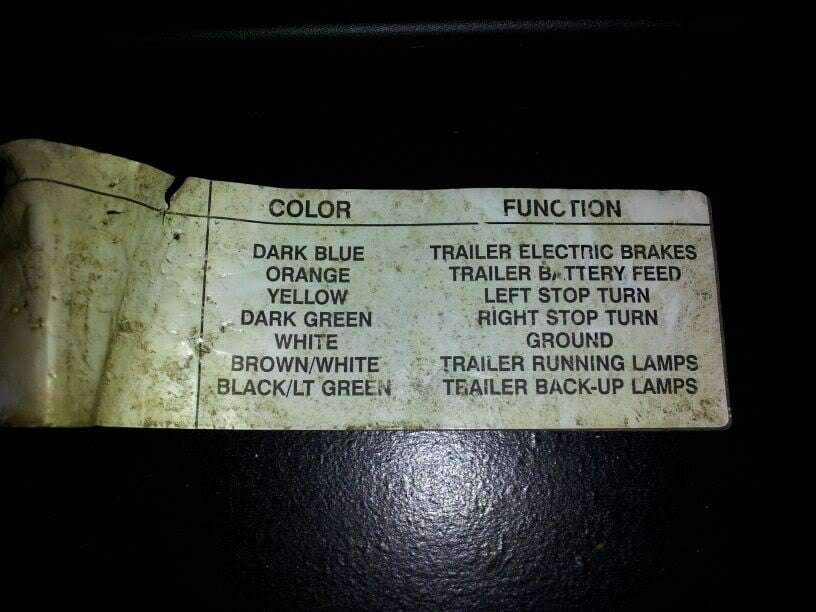

- Locate the drive belt by referring to the owner’s manual or under-hood diagram.

- Loosen the tensioner pulley to free up slack in the belt.

- If replacing the belt, remove it from its pulleys carefully. Check for any damage before installing a new one.

- If tightening the belt, adjust the position of the tensioner pulley and tighten it until there is slight deflection when pressed with moderate finger pressure.

- Start the engine and check if there are any screeching or slipping noises while turning the steering wheel. These could indicate incorrect tensioning of the drive belt.

Remember that not all vehicles have similar procedures for replacing or tightening drive belts. It is always best to refer to manufacturer guidelines before commencing work.

To prevent future issues:

- Regularly inspect and replace worn-out belts.

- Keep pulleys clean and debris-free.

- Never over-tighten or under-tighten a drive belt as this can cause further problems.

Proper maintenance of your vehicle’s drive belts can help prolong their lifespan, prevent hard steering, and keep your vehicle running smoothly overall. Fixing your faulty power steering pump is like replacing a bad boss – it may not solve all your problems, but it makes the ride a lot smoother.

Repairing or Replacing a Faulty Power Steering Pump

To fix problems with hard steering, the faulty power steering pump may need to be repaired or replaced. This involves checking for leaks and inspecting key components such as hoses and belts.

A worn-out pump can result in difficulty turning the wheel, unusual sounds when steering, and decreased performance.

Here is a 4-step guide for resolving issues with the power steering pump:

- Start by inspecting the pump and checking for signs of wear and tear.

- If the problem lies with the power steering fluid itself, you may simply need to refill it or flush out any contaminants.

- For more significant issues, consider repairing or replacing damaged components.

- In some cases, replacing the entire power steering pump may be necessary.

It’s important to ensure that you have a proper diagnosis before proceeding with any repairs. This may involve further testing or seeking assistance from a qualified mechanic.

To prevent future problems with your vehicle’s power steering system, consider following these tips:

- Regularly check fluid levels and replace fluids as needed

- Have your vehicle inspected regularly for signs of wear and tear

- Avoid harsh driving conditions that can put additional strain on your power steering system

By taking these steps, you can maintain optimal performance from your vehicle’s power steering while preventing costly repairs down the road.

Looks like it’s time for the steering gear to retire – hopefully your retirement plans include less grinding and more piña coladas!

Replacing a Damaged Steering Gear

When the steering becomes hard, one possible solution is to replace the damaged steering gear. Follow these steps for a successful replacement:

- Disconnect the negative battery cable and remove any wire or hose that might interrupt the removal process.

- Mark and remove the pitman arm bolt and nut from the steering box.

- Detain the sector shaft locknut using a pipe wrench and turn it counterclockwise using an adjustable wrench.

- Nudge out of position the gear selector linkage with pliers.

- Undo the mounting brackets around the worn-out gear then gently remove it, ensuring not to damage other parts in the process.

- Reattach new steering gear by aligning mounting holes with brackets then install bolts and nuts firmly as specified in your vehicle manual.

It is important to ensure safety during the whole replacement process. Also, get new fluids, and reevaluate wheel alignment accordingly.

A pro tip is to always check for leaks after finishing installation to avoid surprises on your first test drive!

Fixing a faulty steering rack is like trying to fix a bad relationship: sometimes it just needs some adjustments, but other times you gotta cut your losses and find a replacement.

Repairing or Replacing a Faulty Steering Rack

When the steering of your vehicle becomes hard, it’s usually an indication of a faulty rack. You may have to either repair or replace it. Here’s how to get started:

- Begin by jacking up the car and removing the wheels.

- Remove the tie rod end from the old rack and loosen the clamps that hold the boots in place.

- Next, remove the old rack using a wrench or pliers.

- To install a new one, bolt it securely into place using alligator clips and tighten them well.

- Reattach the tie-rod end to the new rack and reconnect any electrical connections if necessary.

- Finally, add power steering fluid back into your vehicle before taking it for a test drive.

It’s important to note that replacing or repairing a faulty steering rack can be tricky. Make sure you follow manufacturer guidelines for proper disassembly and reassembly procedures.

If you notice any leaks in your power steering system or hear unusual noises while turning your wheels, it could be an indication of further underlying problems with your car’s steering mechanism.

In this case, consult with an expert mechanic immediately.

According to AutoGuide.com,

“A damaged or worn-out power steering belt can also lead to problems with hard steering. It’s always recommended that you check all components of the power steering system during routine maintenance.”

Looks like you’ll need to steer your wallet toward repairing or replacing that column.

Repairing or Replacing the Steering Column

Repairing or replacing the steering column requires technical expertise and appropriate tools.

The procedure involves disassembling and installing a new column or repairing and strengthening the existing one. Here’s a 3-step guide to get you started:

- Identify the problem: Inspect the steering column for any cracks, damage, or looseness in bolts. Check if there is any play in the steering wheel while driving. Determine whether you need to repair the existing column or replace it entirely.

- Disassemble and Install: Turn off your vehicle’s engine and disconnect the negative battery cable before starting with disassembly. Remove all electrical connections from column wiring harnesses and unscrew bolts that secure the column to your vehicle’s dashboard. Now, remove your old steering column by gently pulling straight outwards of its mounting brackets gently but firmly. Reverse these steps to install a new steering column.

- Torque Bolts: Use torque specifications as given by manufacturers while tightening bolts on your newly installed or repaired columns using appropriate tools.

Remember these significant points before performing this task:

- Consult manufacturers’ instructions

- Have sufficient knowledge about this technical job

- Follow necessary safety precautions

In addition to these steps, grease and lubrication of joints must be done periodically according to manufacturer recommendations.

Ensure proper maintenance of your car by regularly checking for repairs or replacements required for efficient performance.

Keeping up with regular maintenance is crucial not only for smooth drive but also for safety reasons, so don’t ignore any signs.

Don’t wait until it’s too late; neglecting issues with your car’s driveshaft could cause injury or damage both financially and physically in an unfortunate event.

Steering clear of hard steering is like avoiding a bad blind date – do your research and take preventative measures.

Preventing Hard Steering

To prevent hard steering in your vehicle, you need to take certain measures. Regular maintenance, prompt repairs for any signs of hard steering, using the right power steering fluid, and avoiding overloading or excessive steering input can ensure smooth and easy steering. These sub-sections will discuss each solution in detail.

Regular Maintenance

Professional Maintenance for your Steering System

Maintaining the steering system is crucial in preventing hard steering. Performing certain tasks on a regular basis ensures optimal performance and longevity of your vehicle’s steering system.

Here are 5 important points to keep in mind when maintaining your steering system:

- Check power steering fluid regularly.

- Inspect the belts and hoses for wear and tear.

- Lubricate any joints and linkages to prevent rusting.

- Tighten any loose screws, bolts or clamps.

- Replace worn-out components immediately.

It is also important to note that any unusual noises or vibrations while driving may indicate a problem with the steering system. These should be addressed promptly to prevent further damage and costly repairs.

In addition, regular maintenance not only prevents hard steering but also improves overall handling and extends the life of your vehicle’s tires.

According to Car Care Council, failure to maintain power steering fluids often leads to component failures resulting in expensive repair bills.

Maintaining your vehicle’s steering system through regular checks and maintenance will not only ensure safety while driving but also save you money in the long run.

Fix your hard steering before it fixes your face – prompt repairs are a must!

Prompt Repairs for Any Signs of Hard Steering

When experiencing difficult handling while directing your vehicle, it is necessary to address any discernible signs of stiff steering.

Failure to do so may jeopardize your control over the car and lead to potentially hazardous situations. In order to prevent this from happening, follow these five simple steps:

- Begin by inspecting the power steering fluid levels as inadequate levels can be a major cause of difficult steering.

- If fluid levels are not the issue, examine the belt that powers the power steering pump as it may be either slipping or damaged.

- Check if there are leaks in areas such as pressure lines, pumps or hoses and repair them immediately.

- Inspect for wear and tear in components including knuckles, tie rods ends or ball joints that can contribute towards poor handling and replace them if required.

- If all these measures fail to solve the hard steering issue, seek professional mechanical advice before driving further.

In addition to adhering to these steps, drivers should bear in mind that even inconsistent difficulties with steering require attention. Due care should be taken to ensure that every effort is made towards maintaining safe driveability.

Pro Tip: Regular maintenance such as oil changes and service checks can help identify potential problems early on before they escalate into more serious issues.

Pouring anything but power steering fluid into your steering system is like putting milk in your gas tank – it’s just not gonna work.

Using the Right Power Steering Fluid

Proper Fluid for Smooth Power Steering

Without the appropriate power steering fluid, your vehicle’s steering system may become stiff or unresponsive.

Using the correct fluid can reduce the wear and tear on your components, and enhance performance and safety.

Using the Right Power Steering Fluid:

- Ensure to use manufacturer-recommended fluids.

- Inspect and replace fluids at recommended intervals.

- Do not mix different types of power steering fluid.

- Avoid using universal or generic fluids.

Additionally, mismatched fluids can cause leakage, and corrosion and may even destroy internal seals. Always use compatible and high-quality fluids from reputable manufacturers.

Furthermore, improper fluid selection can lead to a failed power steering pump; this could create premature engine failure from overheating.

As such, always follow the manufacturer’s instructions precisely when selecting your power steering fluid.

To get the most out of your vehicle’s steering system, use suitable quality fluid at every change point to keep it running at peak capacity.

Finally, when possible, avoid opting for general operators that could damage your car. Steering clear of overloading is key unless you want to experience a spin-off worthy of a Hollywood blockbuster.

Avoiding Overloading or Excessive Steering Input

Excessive Input On The Steering Wheel Can Cause Hard Steering. To Avoid This, Proper Measures Need To Be Taken.

To avoid overloading or excessive steering input, follow these 6 Steps:

- Make sure that you are not carrying any excess weight in your vehicle to avoid overloading the car’s capacity.

- Use both hands while holding the steering wheel for better control and prevention of overworking.

- Avoid using one hand on the shifting stick frequently as it can cause a disturbance in balance and affect the steering system at high speeds.

- Opt to use minimal force while turning and avoid abrupt and quick changes as they could harm the tires’ grip and decrease steering responsiveness.

- Avoid speeding on rough terrain as it could cause excessive vibrations and damage pipes, plates, rods, bearings, etc., leading to hard steering problems.

- Maintain regular servicing of your vehicle inclusive of wheel alignment checks and tire balancing procedures provided by reputable service stations to ensure safety standards compliance.

Take Note That Well-Maintained Vehicles With Low Mileage Experienced Fewer Issues Of Hard Steering.

Maintaining proper weight capacity and taking caution with consistent two-handed usage of your vehicle’s wheel will improve your overall driving experience.

Let’s steer clear of hard steering and avoid turning our cars into death traps.

Final thoughts

The root cause of a hard to turn steering wheel is often linked to issues with the power steering system. Common problems range from low power steering fluid levels to faulty power steering pumps or belts.

The solution may involve simply adding more fluid, replacing parts, or identifying and fixing leaks. Regular maintenance can help prevent these issues from arising in the first place.

One factor that can contribute to hard steering is worn or damaged tie rod ends.

These components connect the wheels to the steering system and can become loose over time. Other potential culprits include poor wheel alignment, uneven tire wear, and worn ball joints.

It’s important to address any difficulties with your car’s steering as soon as possible, as driving a vehicle with compromised control can be unsafe.

If you’re experiencing any persistent issues with your steering, it’s best to consult a trusted mechanic for advice and solutions.

On a particularly icy winter day, my sister found herself struggling to steer her car on the slick roads.

Despite her efforts, the wheel remained stiff and unresponsive – making it difficult for her to keep the car on course.

After having her vehicle inspected by a professional mechanic, she learned that an issue with her power steering system was causing the problem.

Once resolved, she was able to safely navigate the treacherous conditions without incident.